Ultrasonic cutting and welding of webbing and netting

We are committed to provide our customers with technical textile solutions that combine precision, quality, and durability. Ultrasonic cutting and welding are innovative, high-performance technologies suitable for a wide range of materials and applications.

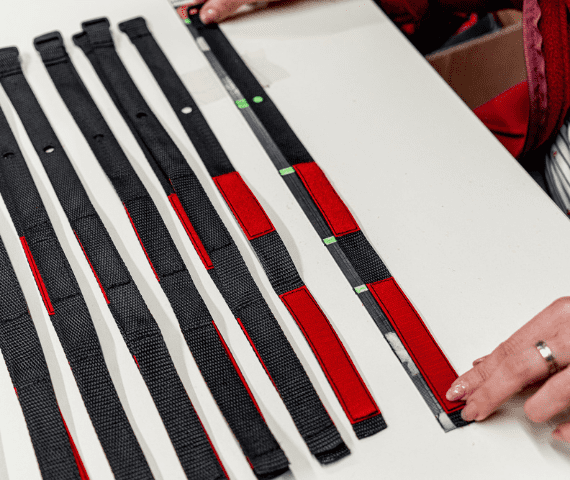

This process can be used to make holes of all shapes, welds, and cuts on a variety of materials. The advantage of this technique is that it “cauterises” the finished product. This guarantees a high level of precision and quality and ensure a clean, fray-free finish to the textile.

In-house expertise

Eurosandow manufactures technical textile products used in demanding sectors such as the automotive, aeronautical, railway and defense industries.

We manage our production process from A to Z to meet our customers’ most specific requirements. Finishing stages and assembly are carried out in-house by our experienced teams.

We regularly invest in new machines to optimise our production process and guarantee our customers responsiveness and short shipping time.

Our factory has 6 ultrasound machines, enabling both manual and automatic production. This infrastructure gives us the flexibility we need to handle orders of all sizes within the best time frame.

Our commitment to quality allows us to design and manufacture high-performance textile solutions that meet the highest standards of each industry.

Applications

Our expertise guarantees robust solutions tailored to the specific requirements of each application.

Automotive

We produce a wide range of webbing, such as seat manoeuvring straps and tubular headliner straps, as well as storage nets, such as seat back, pocket and boot nets.

These products are essential in the automotive industry and must meet strict standards in terms of safety, durability and practicality.

Aeronautics

In aeronautics, ultrasonic cutting can be used as a finishing stage on nets placed on cabin seats to store documents and safety instructions. They are then assembled on a stainless steel frame and comply with current fire safety standards.

Rail

In the rail sector, ultrasonic cutting can also be applied to nets used for storage at the back of seats, as well as to safety nets designed to prevent objects or luggage stored at height from falling out.